| Material | Rigid Vinyl Chloride (Self-extinguishing property 94 V - 0) |

|---|---|

| Color | Gray |

| Standard length | 2m |

| Operating temperature | -20℃to50℃ |

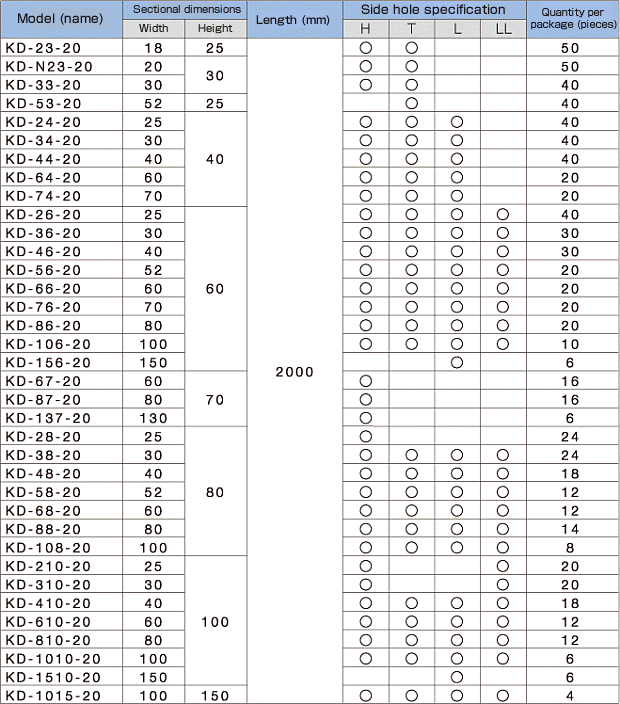

Part numbering rule

KD-(model)-(length)-(side hole)

Example: Model: 26, length: 2 m, side hole: H type, KD – 26 – 20 – H

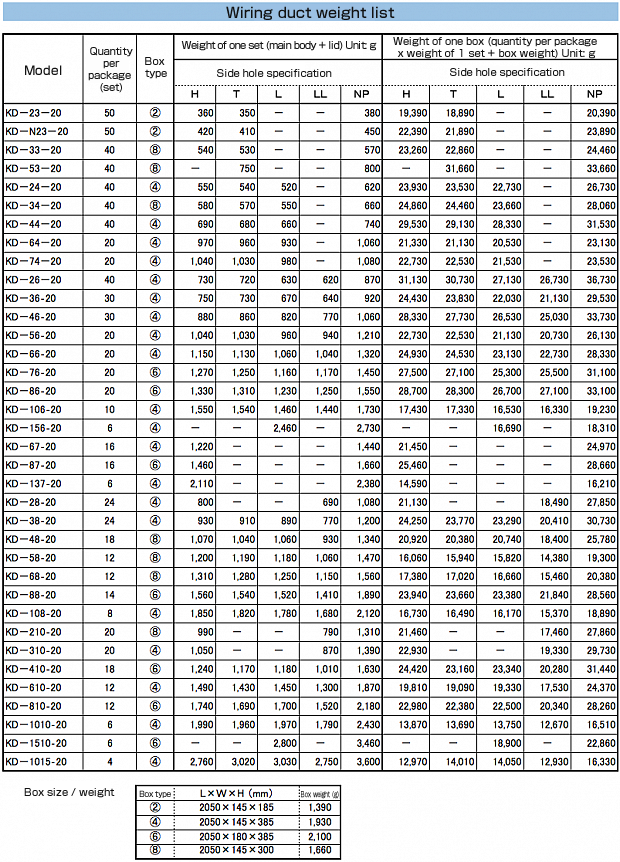

Type List

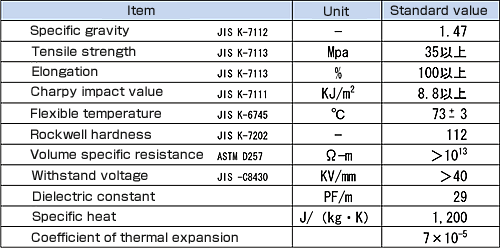

Properties (physical properties)

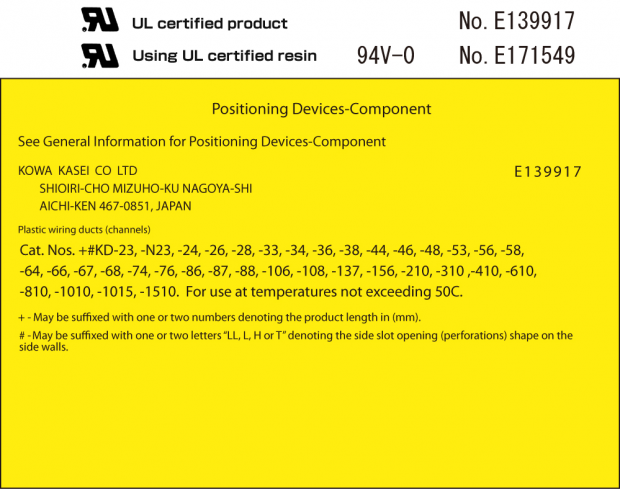

UL standard certification

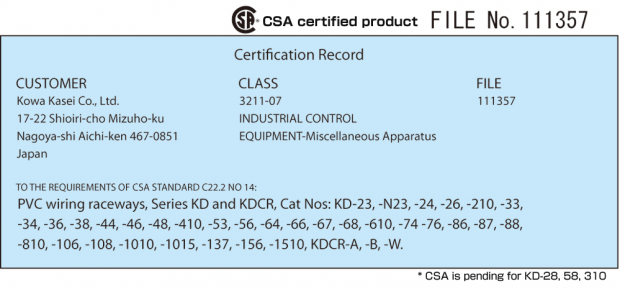

CSA standard certification

Introduction of side hole type features

H Type

Standard size side hole. Because the interior is hard to see, it looks nice on the exterior.

H type also has the largest variations in size.

T Type

A slit is put partway up to the upper part of the standard size side hole. The joint can be cut with a simple tool such as a nipper.

L Type

Hole is larger than H and T types and workability is good.

LL Type

The largest side hole type.

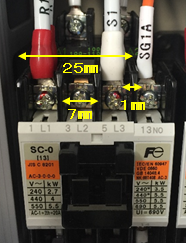

The side hole pitch is 25 mm, making it easy to wire because the pitch is close to the wire connection pitch of the equipment.

We can also prepare types without wiring holes.

Features

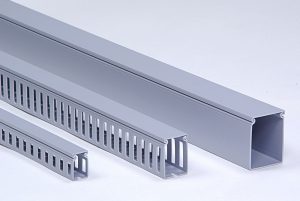

●Improvement of appearance and space saving can be achieved by using it for protection around machines and machine wiring.

●There are no wiring holes, preventing dust and other intrusions.

Part numbering rule

KD – (model) – 20 – NP – with or without bottom hole

* Please select whether you require a bottom hole.

Example: KD duct model 26 with bottom hole

KD – 26 – 20 – NP with bottom hole

NP Type

A type without a side hole.

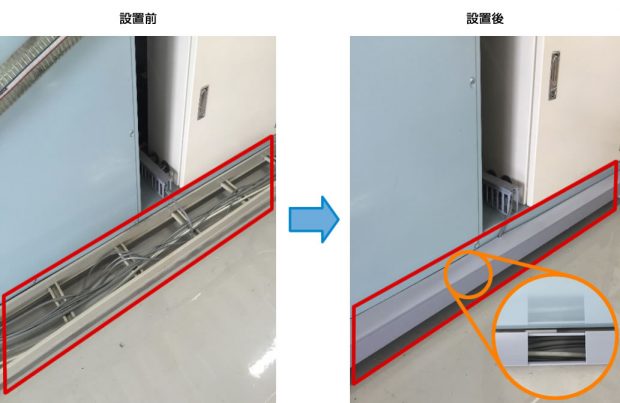

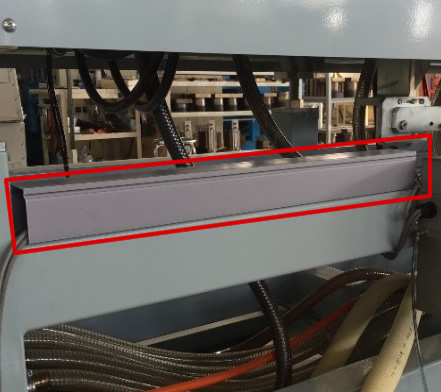

Examples of use

(1) Space saving / External appearance improvement

By replacing cable rack (W: 200 mm) with KD – 66 – 20 – NP (W: 60 mm),

space saving and appearance improvement was realized.

(2) Prevention of dust intrusion / appearance improvement

By protecting the exposed cables with NP ducts, dust intrusion was prevented and the appearance was improved.