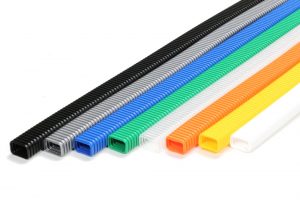

Wiring flexible tube case study

Company B manufactures printed circuit boards and harness processed products for medical and other device manufacturers.

Company B manufactures printed circuit boards and harness processed products for medical and other device manufacturers.

The company was using spiral tubes for wire protection, but examined our product as a tube that can work more easily than a spiral tube in a project for a new model.

As a result of trial use of the sample, since the tube was flexible and allowed the insertion of wire without using an insertion tool, the company found that the wiring work could be done very quickly compared with spiral tube and decided to adopt the system.

The price will be slightly higher than the spiral tube, but Company B estimates that it will be cheaper in total when considering the labor man-hours and later maintenance. Also, their customer remarked that the appearance was improved compared to conventional products.

Wiring flexible tube introduction flow

- Reducing work man-hours ⇒ It is time-consuming to wind spiral tubes.

- It is time-consuming to remove spiral tubes when additional wiring is done later.

- Request for a product with good workability that can replace a spiral tube

- Able to reduce man-hours

- Helped to improve the appearance

- Additional wiring can also be easily done