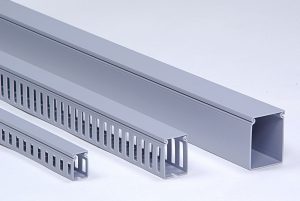

Case studies of wiring duct processing service

Company T is a panel maker focusing on the distribution board and control board production business for major electric manufacturers.

Company T is a panel maker focusing on the distribution board and control board production business for major electric manufacturers.

With a large order for panels of the same type, The company took interest in the service that we proposed, aiming for efficient manufacturing, and decided to adopt it.

After introduction of the service, they achieved reduction of invisible costs such as labor man-hours, inventory control and processing cost of duct material leftover. Initially, Company T worried that the purchase cost of the parts would rise, but ultimately rated our service very highly since it led to a reduction in total costs.

Wiring duct processing service introduction flow

Issues before introduction

- Calculation of the required duct size, number of parts, etc. is time-consuming.

- Duct cut quality differs depending on the skill level of the worker.

- Sometimes losses are caused by processing errors.

- The cost of disposing of duct material leftover is high.

Requests

- Cutting down various labor man-hours in mass production projects

Achievements / Improvements

- Significant improvement in labor man-hours

- By adopting set packaging, order management became extremely easy.

- By adopting the service, the total cost of work was drastically reduced.

- Eliminated losses due to processing errors