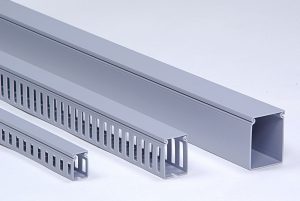

Case studies of wiring duct processing service

Company K designs and manufactures high-voltage power receiving equipment, and as a result of various investigations in order to respond to requests from customers for quick delivery, decided to introduce our service.

Company K designs and manufactures high-voltage power receiving equipment, and as a result of various investigations in order to respond to requests from customers for quick delivery, decided to introduce our service.

We make drawings of the ducts through design meetings with the design staff of the company and delivers the processed duct in a set package box for each production number. The company is very much satisfied that they can install the product immediately after accepting the product.

In addition, Company K is also very happy that it can effectively utilize space made thanks to a reduction in inventory of standard items, and the amount of duct material leftover also decreased, leading to improved environmental performance. The company now mainly uses our service for production planning and highly values it, introducing it to partnering companies.

Wiring duct processing service introduction flow

- Eliminating as many cutting processes as possible

- Reducing inventory (Securing the space is necessary for standard items because the boxes are large)

- Problems with storage and disposal of duct material leftover

- Keeping duct processing quality constant

- Eliminating losses due to processing errors

- Short delivery time (delivered in four business days from order placement)

- Small lots supported

- Additional processing to side holes and bottom surface

- Work efficiency improved thanks to elimination of processing work on side holes and bottom surfaces.

- Reduced inventory, leading to space saving at workplace

- Short delivery time increased trust by responding to the customer’s requests

- Reduced cost such as expenses for disposal of duct material leftover

- Ensured safety during operations and eliminated losses due to processing errors