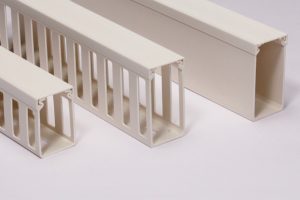

Case studies of halogen-free flame retardant PP duct introduction

Company D offers various types of semiconductor manufacturing equipment, and its end users are diverse with customers in Japan and abroad. In recent years, the company became interested in adopting halogen-free flame retardant PP ducts as the keyword “halogen free” has become more well-known from the viewpoint of the environment, and decided to adopt the product.

Company D offers various types of semiconductor manufacturing equipment, and its end users are diverse with customers in Japan and abroad. In recent years, the company became interested in adopting halogen-free flame retardant PP ducts as the keyword “halogen free” has become more well-known from the viewpoint of the environment, and decided to adopt the product.

The ECO duct which had been part of the existing product lineup has problems such as being hard and fragile and having poor performance with respect to oils such as lubricants due to its material properties. However, this duct not simply solved these problems but also made it possible to realize cost reduction of the product itself by using polypropylene.

Company D highly regards the fact that the product not only satisfied their requested specifications but also lowered cost of their products, compared with the conventional ECO duct.

Halogen-free flame retardant PP duct introduction flow

- ECO duct is more expensive than PVC(polyvinyl chloride) ducts

- The material of the ECO duct is hard and requires force when cutting. Poor resistance to oil

- Delivery time is longer than PVC duct

- Quick delivery service (within 3 to 4 business days)

- Hardness that can be easily cut even by female workers

- Reduce the purchase cost as much as possible

- It is flexible and even a female worker can easily cut it

- The purchase cost of the parts drastically decreased

- Excellent heat resistance, far better specifications than PVC duct

- Availability is good and work can proceed as planned